About the Calculator

The Calculator

Meet REFINERY CALCULATOR – we are your refinery, petrochemical, industrial gas, power, natural gas and energy information supplier. The REFINERY CALCULATOR team provides end users with a unique, easy to use, on-line and back end Excel based refining simulator to provide you with information at your finger tips.

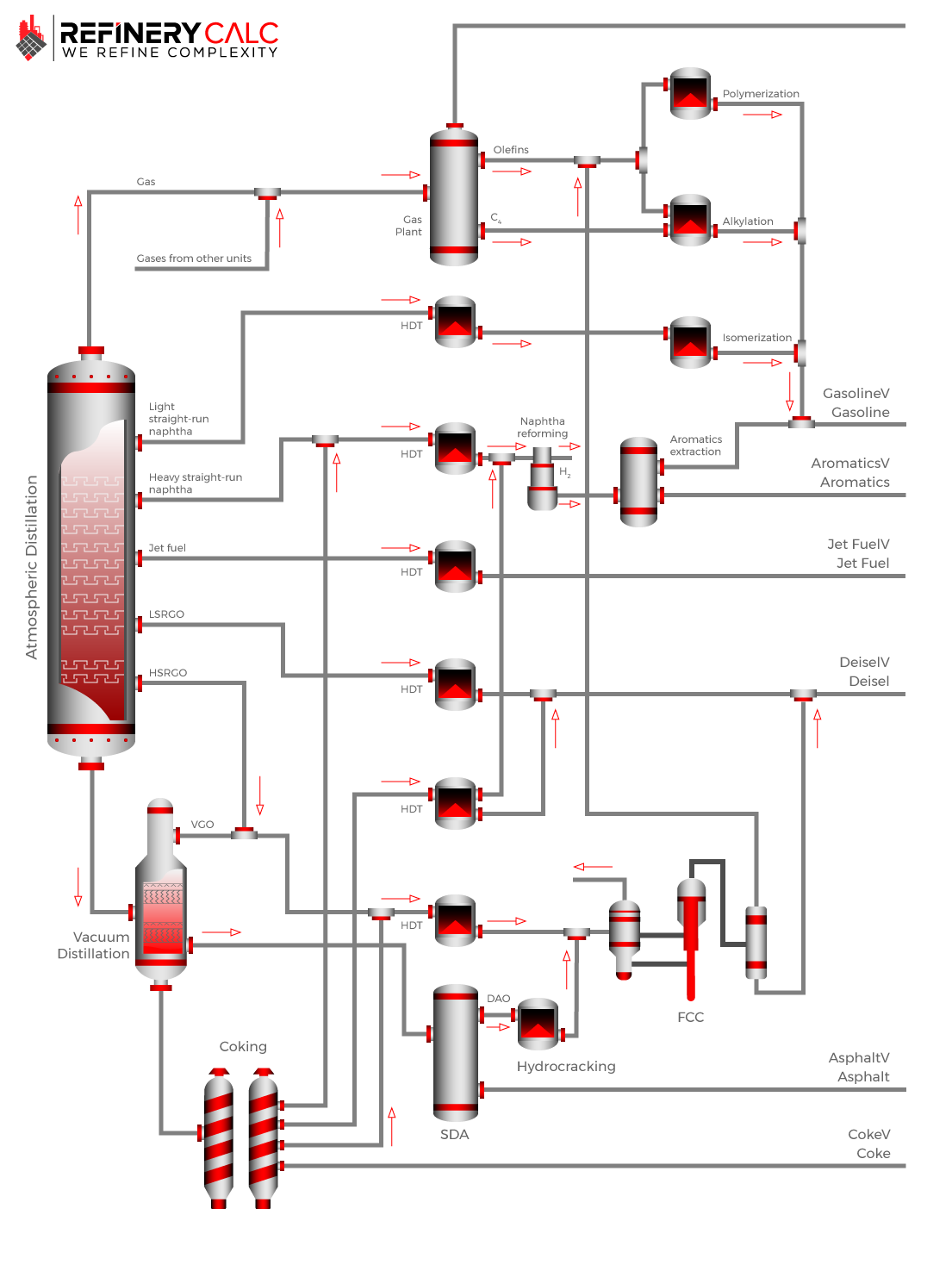

We have developed a proprietary and rigorous techno-economic refinery simulator that optimizes! The simulator can configure itself to any refinery in the world and provide valuable and insightful information to the user.

The REFINERY CALCULATOR model has proprietary process yield correlations and configurations for nearly every complex refinery in the world. For the upgrader and specialty refineries our clients can provide us with an order for a custom simulation and we will use our offline version of the tool to provide the same value added services.

The REFINERY CALCULATOR team has worked earnestly to simplify our highly sophisticated software package and equip users with the ability to use the tool with very little training.

Features

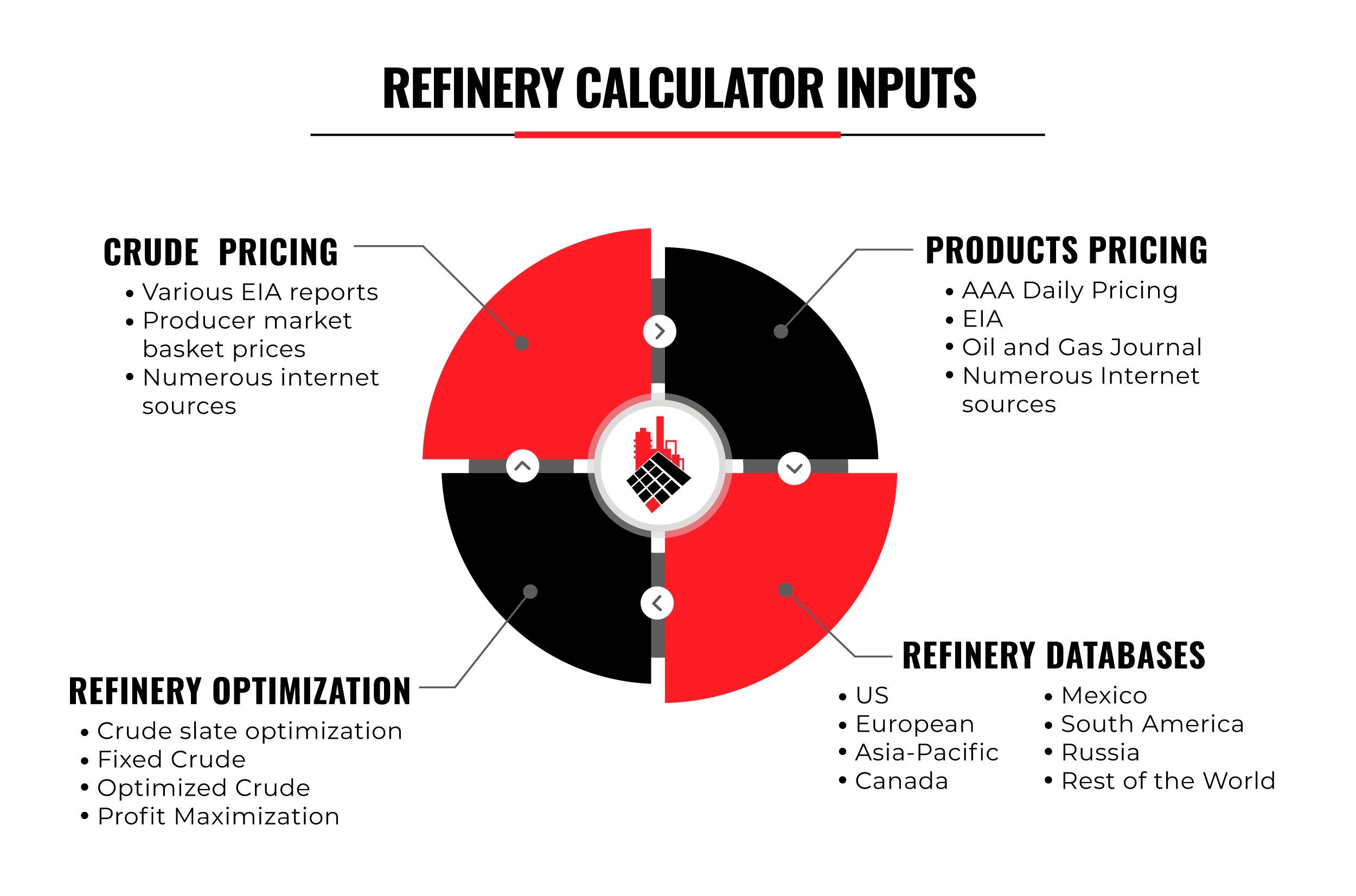

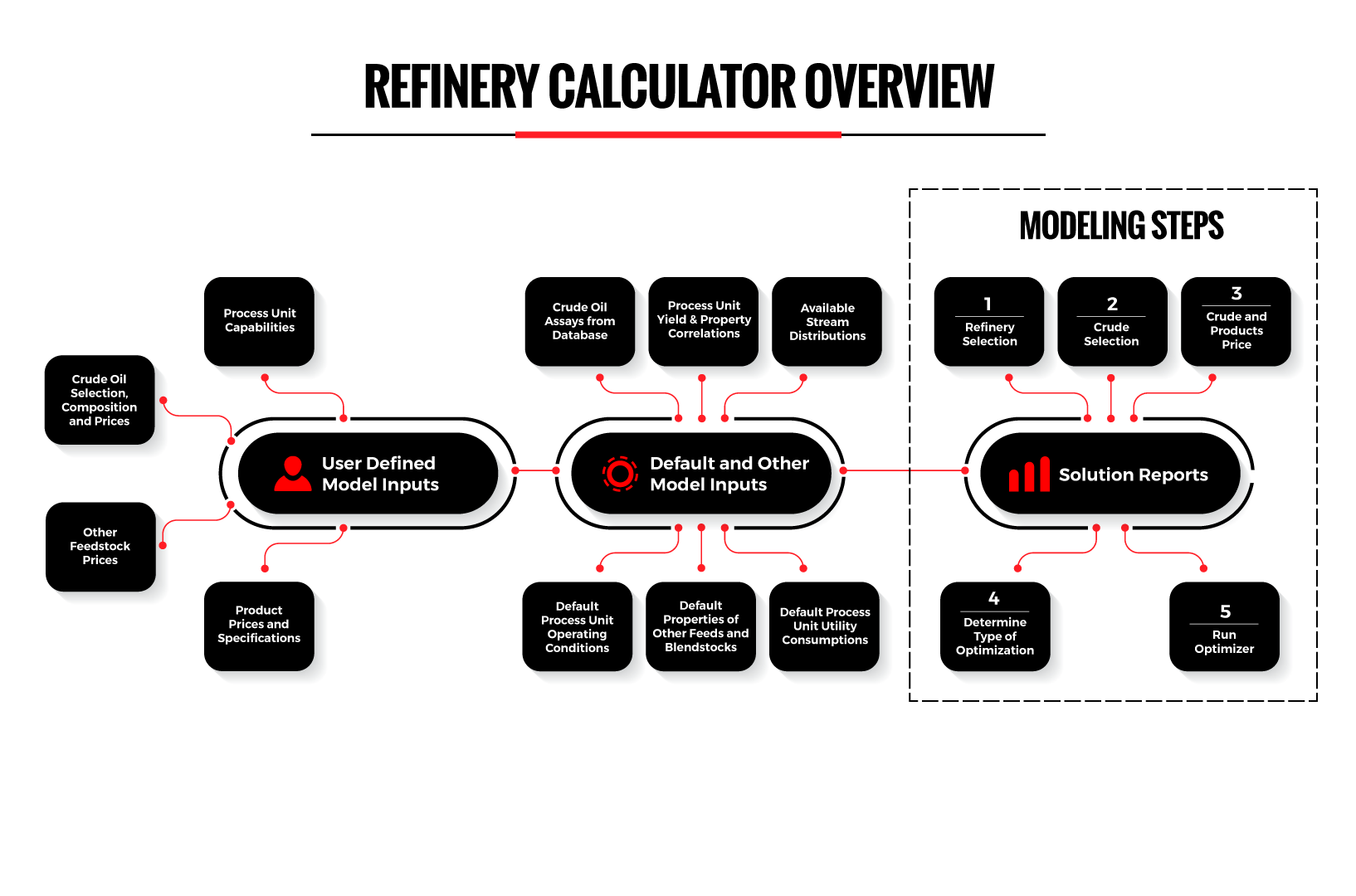

provides users with the ability to specify the following information to perform a simulation of nearly any refinery in the world or even a “green field” refinery:

Other Unique Features of the Refinery Calculator include:

01.

INPUTS

First select nearly any complex refinery in the world, adjust any of the processing unit configurations either upward or downward, next select up to 5 crude oil types, then adjust crude prices, ‘cut-points’ and product prices. Users can utilize the pricing information that the Refinery Calculator team provides or use his/her own pricing information.02.

SIMULATE

Simply hit the Run Refineries button to begin the process simulation. On average each refinery run takes less than 2 minutes. The time of the simulation varies based on the number of refineries selected, the types of crudes and any modifications to the configurations.03.

OUTPUT

Once the model completes the simulation there are several web based reports that a user can view and then print to a .pdf file – plus the user can download the data output file from the simulation. Lastly, if a user wants more specific data from any particular process unit – the Refinery Calc team would be happy to assist in providing a custom solution or report addition for your model run.Model Functionality

The model performs the following functions based upon the user-defined inputs and a standard set of proprietary assumptions based upon many years of refinery operations and engineering experience:

Crudes

Over 200 of the world’s most popular crude assays are available for use with the Refinery Calculator. We can even insert your specific crudes if provided with an assay.Crude Units

We have modeled units in each refinery across the world. You will be running the refineries at the designed capacity to know exactly what is happening in the real world| Crude Unit |

|---|

| CRUDE UNIT |

| VACUUM DISTILLATION |

| ALKYLATES |

| AROMATICS |

| ASPHALT & ROAD OIL |

| CAT CRACKING: FRESH FEED |

| CAT CRACKING: RECYCLED FEED |

| CAT HYDROCRACKING, DISTILLATE |

| CAT HYDROCRACKING, GAS OIL |

| CAT HYDROCRACKING, RESIDUAL |

| CAT REFORMING: HIGH PRESSURE |

| CAT REFORMING: LOW PRESSURE |

| DESULFURIZATION, DIESEL FUEL |

| DESULFURIZATION, GASOLINE |

| DESULFURIZATION, HEAVY GAS OIL |

| DESULFURIZATION, KEROSENE AND JET |

| DESULFURIZATION, NAPHTHA/REFORMER |

| DESULFURIZATION, OTHER |

| DESULFURIZATION, OTHER DISTILLATE |

| DESULFURIZATION, RESIDUAL |

| FUELS SOLVENT DEASPHALTING |

| HYDROGEN PLANT AND PSA (MMCFD) |

| ISOMERIZATION (ISOBUTANE) |

| ISOMERIZATION (ISOPENTANE/ISOHEXANE) |

| LUBRICANTS |

| OPERATING CAPACITY |

| PETCOKE,MARKET |

| SULFUR (SHORT TONS/DAY) |

| THERM CRACKING, DELAYED COKING |

| THERM CRACKING, FLUID COKING |

| THERM CRACKING, OTHER (INCLDNG GAS OIL) |

| THERM CRACKING, VISBREAKING |

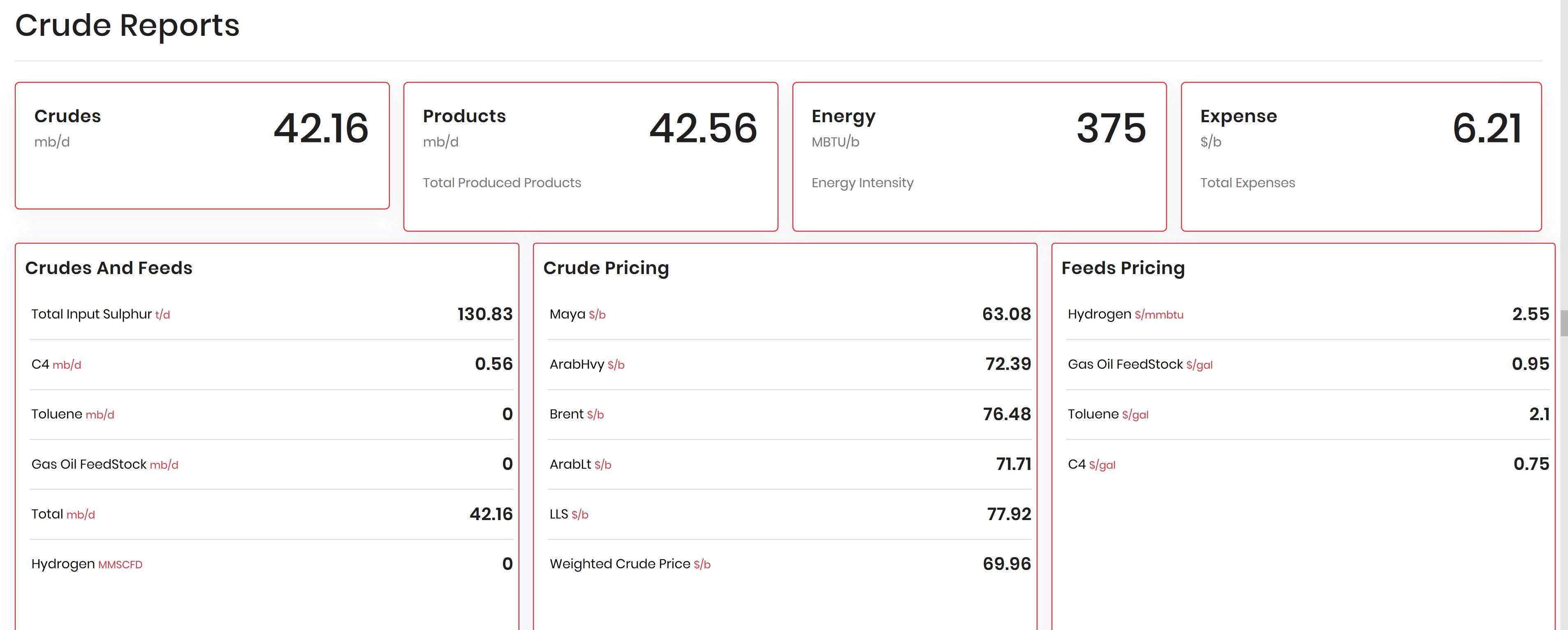

Web Based Report

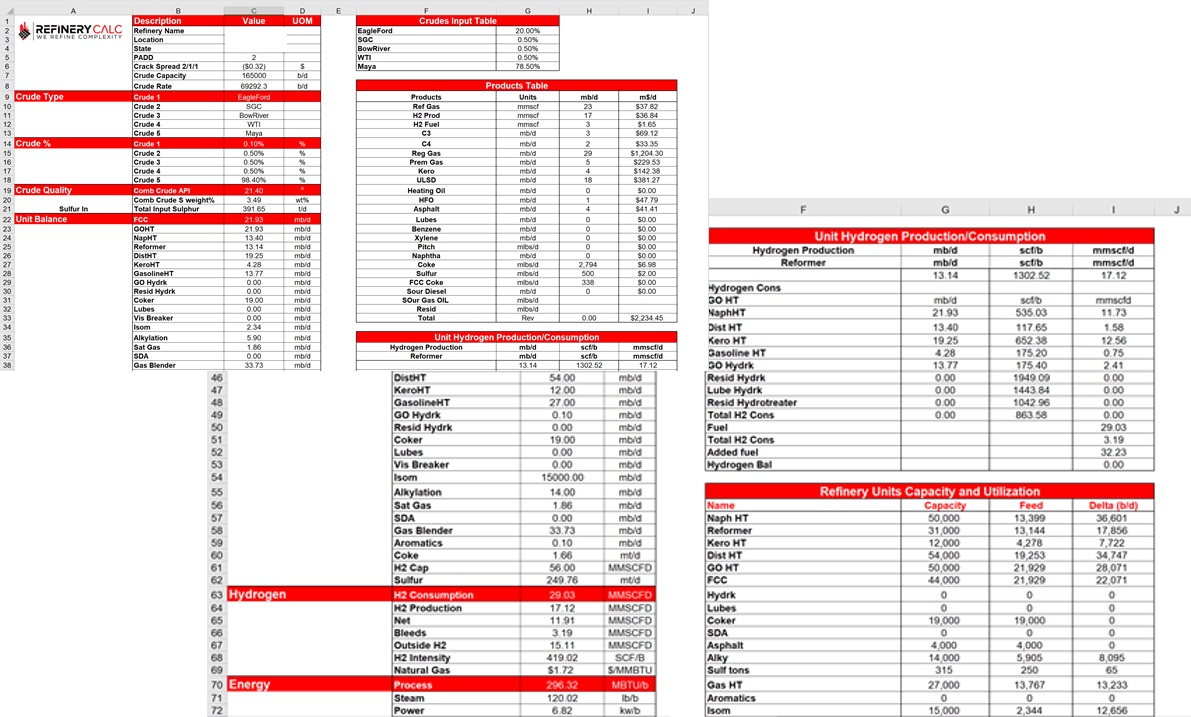

Upon running each refinery, you will get an immediate report that looks like the following

Detailed Report

You will be able to download the raw data file that helps you to further analyze the data any way you wish

Use Cases

Under What Scenarios Will the Calculator be Used?Custom Solutions

No job is too large or small for the Refinery Calc team. Consider us your partner in helping you generate custom reports or data packages for refineries that may include specifics about, energy, industrial gases, chemicals, carbon emissions, green hydrogen, crude pricing, product yields, refinery margins, feasibility studies, refinery expansions or any other type of question you can come up with. We are here to support your needs

Unlimited Support

Five days a week M-F during normal business hours. Also, feel free to send us an email at [email protected]

Start A FREE Trial Now

See the power of this calculator by trying it for 1 day.